The BASF Corporation did a Structural Insulated Panel (SIP) time and motion study in 2006. BASF was interested because they manufacture (1) the resins used to make Oriented Strand Board (OSB) panels, (2) the Expanded Polystyrene (EPS) foam materials used for the SIP core, and (3) the adhesive used to join the EPS foam core panels to the OSB skins to create SIPs, a highly engineered composite wood product.

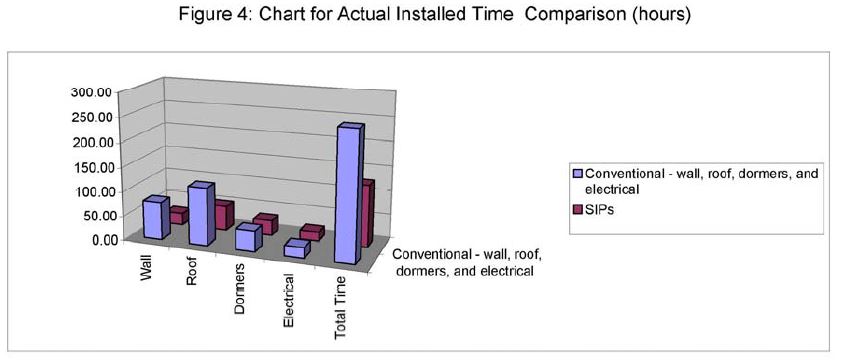

BASF did not do the study internally themselves, they commissioned a third party (Reed Construction Data/RSMeans) to provide independent validation of labor and productivity savings available to all manufacturers. This next chart summarizes their time study findings.

Their research objective was to evaluate the installation time and cost associated with SIP home construction in great detail, as compared with conventional framing comprised of 2 x 6 framing, and oriented strand board (OSB) sheathing, to which thermal insulation and an air barrier are added.

SIPs are load-bearing components that form structural exterior wall assemblies, complete with sheathing, insulation, and air barrier. It was expected that because SIPs eliminate a few steps in the building process, it would speed up construction job site time.

Specifically, the Time & Motion Study would quantify the following productivity differences of conventional framing vs. SIP panels covering (a) Labor and cost savings, (b) Greater efficiencies and ease of use over conventional framing methods, and (c) Productivity differences for residential framing and electrical rough-in.

At this point completion cost of the insulated structures would be expected to be the same for SIP or stick framing, meaning ready to finish the interiors with gypsum board, doors, windows, trim, and paint plus the roofing and exterior wall veneer of choice.

One item I noted was that, while SIP construction is sealed and does provide an excellent insulated air barrier, the SIP exterior OSB would still receive a typical nailed on moisture barrier such as Tyvek (DuPont) before cladding. This would add a very small amount of time to the SIP side of the comparison.

To read the detail of the BASF 2006 Study find the entire report online at SIPA at this above link. BASF did an additional study in 2008 which found a 55% reduction in framing labor - this 2008 framing study is summarized on this SIPA page.